Scientists Develop Free-sealed High-Voltage Aqueous Polymeric Sodium Battery Enabling Operation in Water or at -25 °C

Electric vehicles and flexible electronics get into a new period of vigorous advancement in urgent need of a safe, high-energy and sustainable battery that can be hit, bent, and even soaked in water or under subzero temperature to retain the electrochemical performance.

Among various energy storage technologies, aqueous rechargeable sodium ion batteries (ASIBs) with non-flammable aqueous electrolyte attract intensive interest in energy storage system owing to their inherent safety, nontoxicity and low cost.

Traditional “water-in-salt” electrolyte with highly concentrated fluorinated salts and molecular-crowding aqueous electrolyte via confining water molecules in a crowding poly(ethylene glycol) (PEG) network suffers from poor low temperature performance owing to its salting out at low temperature, high freezing point, and sluggish charge transport kinetics of the electrolyte-electrode interfacial interphase layer.

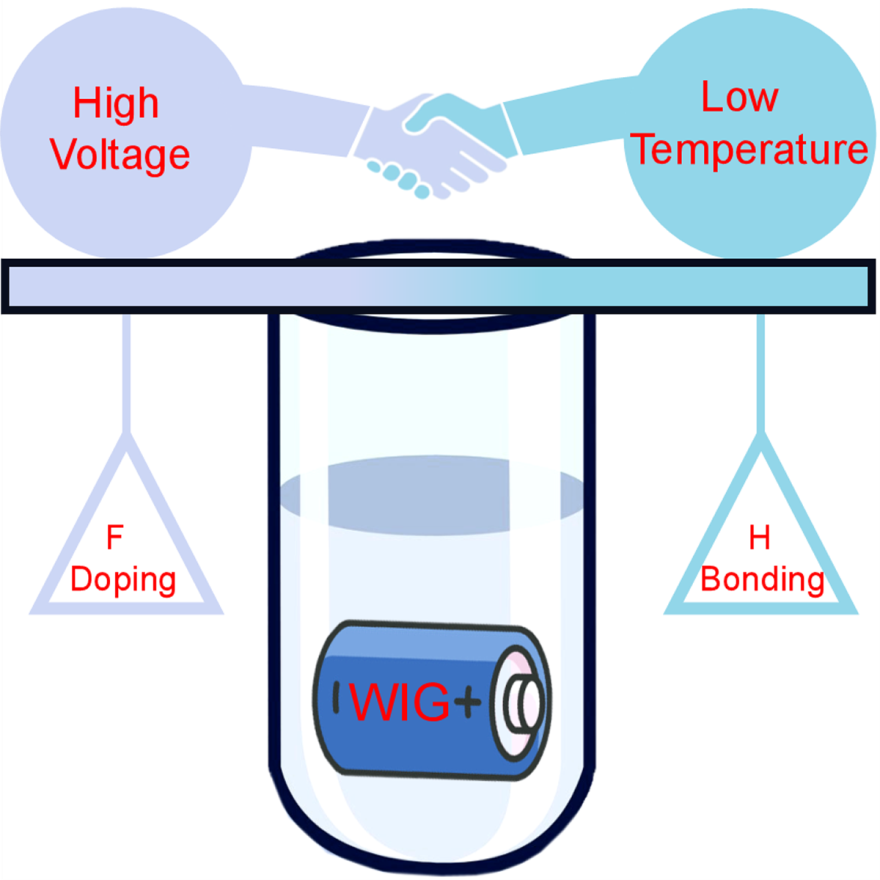

Researchers from the Shanghai Institute of Ceramics of the Chinese Academy of Sciences proposed a novel ‘water-in-ionogel’ (WIG) aqueous polymeric electrolyte that allows a high operational cell voltage (3.0 V) with a high H2O content (10% H2O) and a low salt concentration (2m NaTFSI) for low-temperature operation. The study was published in Cell Reports Physical Science.

The water in copolymerized PEG derived poly(ethylene glycol)methyl ether methacrylate (PEGMA) and bisphenol A ethoxylate dimethacrylate (BEMA) to form cross-linked gels could form an antifreezing solid-electrolyte by changing hydrogen bonding. Furthermore, a typical electrolyte additive, fluoroethylene carbonate(FEC) was introduced in the PEGMA-BEMA system to form O-H…F bonds to weaken the H-bond network in aqueous solution for lowering the freezing point and construct the solid electrolyte interphase for accessible ion diffusion at low temperature.

A polymeric aqueous sodium ion full cell consisting of a Mn-based cathode and hard carbon anode could deliver a high energy density. More importantly, the eco-friendly aqueous polymeric battery could be free-sealed to be an ultrathin, light battery, and perform well under severe conditions, such as being bent, cut, soaked in water or put on fire.

This was the first attempt to realize a high-voltage aqueous electrolyte for low temperature operation. The team will devote to improving the voltage window and transport properties of water-in-ionogel electrolytes in the future for low-cost, sustainable energy storage, which can perform well at subzero temperature or in water.

Image of the “F doping” and “H-bonding” design of “water-in-ionogel” electrolyte for low-temperature and in-water operation (Image by SICCAS)

Reference:https://doi.org/10.1016/j.xcrp.2022.100805

Contact:

Huang Fuqiang

Shanghai Institute of Ceramics

E-mail: huangfq@mail.sic.ac.cn