Interface Modification to Improve the Performance of Perovskite Solar Cells Based on Carbon Electrodes

Solar cells can realize efficient conversion of solar energy to electric energy without environmental pollution and carbon emissions. The highly efficient solar cells will help to reach peak carbon emissions and achieve carbon neutrality.

Perovskite solar cells feature high efficiency, high defect tolerance, solution process and low cost. They exhibit excellent performance in both single-junction and multi-junction solar cells. The noble metal electrode restricts the reduction of the device cost, while the carbon electrode has the merits of low cost, simple preparation methods and high stability. The fully printable perovskite modules based on carbon electrodes with the area of >70 cm2 have achieved an efficiency of more than 13% so far, and the device shows excellent stability.

However, there are insufficient interfacial contact and severe energy mismatch in perovskite/carbon electrode interfaces. In addition, the thermal treatment process of printed carbon electrodes would cause damages to the perovskite film beneath the carbon electrodes.

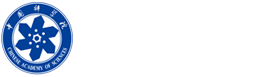

Recently, the research team led by Prof. YANG Songwang from Shanghai Institute of Ceramics, Chinese Academy of Sciences has made progress in perovskite solar cells based on printed carbon electrodes. In order to improve the poor contact in the carbon electrode/CsPbI2Br perovskite interface and energy level mismatch, they introduced carbon black nanoparticles to construct a carbon black interlayer and therefore optimize the extraction of carriers.

The work function of the carbon black interlayer (-5.10 eV) locates between the valence band maximum of the CsPbI2Br perovskite (-5.44 eV) and the work function of the carbon electrode (-5.03 eV), which can reduce the interface energy mismatch.

Besides, the carbon black interlayer is dense and uniform, which contributes to the sufficient interfacial contact between the CsPbI2Br perovskite layer and the carbon electrode. The above advantages ensure an effective extraction of photogenerated holes, and the efficiency of the optimal device reaches 13.13%.

Moreover, the device based on the carbon black interlayer maintains about 90% of its initial efficiency after continuously heating treatment at 85 oC for 2000 hours, showing good thermal stability of CsPbI2Br solar cells based on carbon electrodes.

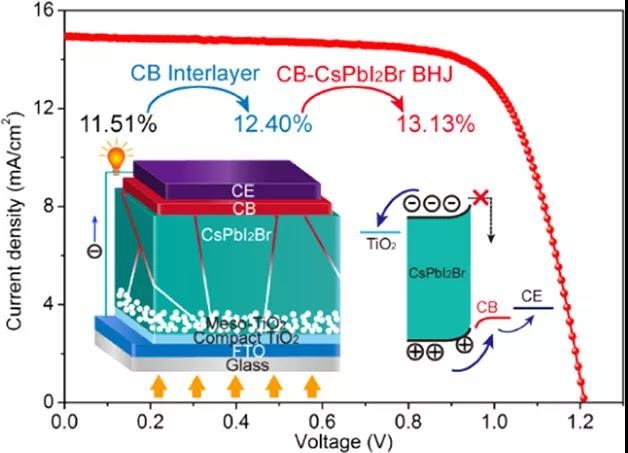

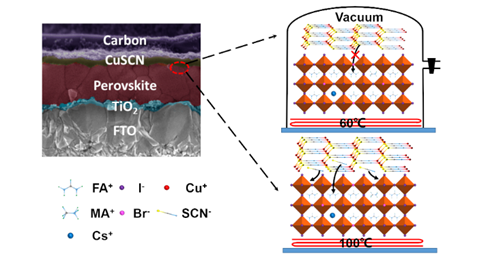

On the other hand, in order to further enhance the efficiency of carbon based solar cells, they introduced an inorganic CuSCN hole transporting layer between the (CsFAMA)Pb(IBr)3 perovskite and the carbon electrode to improve the hole extraction and device efficiency. They demonstrated the heating process of the carbon electrode under high temperature (~100 oC) caused the diffusion of SCN- into the perovskite layer and therefore reduced the performance of the device.

To solve this problem, they developed a vacuum-assisted drying process for the preparation of carbon electrodes. This process can accelerate solvent volatilization at a lower temperature (<60 oC), which inhibits SCN- diffusion caused by the heating process, and improve the efficiency of the device to 15.72%.

Furthermore, the stability test showed that the device still maintained about 85% of its initial efficiency after 300 hours of continuous light soaking or 1000 hours of storage (unencapsulated), indicating the good stability.

The above results were published in ACS Applied Materials & Interfaces entitled"CsPbI2Br Perovskite Solar Cells Based on Carbon Black-Containing Counter Electrodes" and "Vacuum-Assisted Drying Process for Screen-Printable Carbon Electrodes of Perovskite Solar Cells with Enhanced Performance Based on Cuprous Thiocyanate as a Hole Transporting Layer"

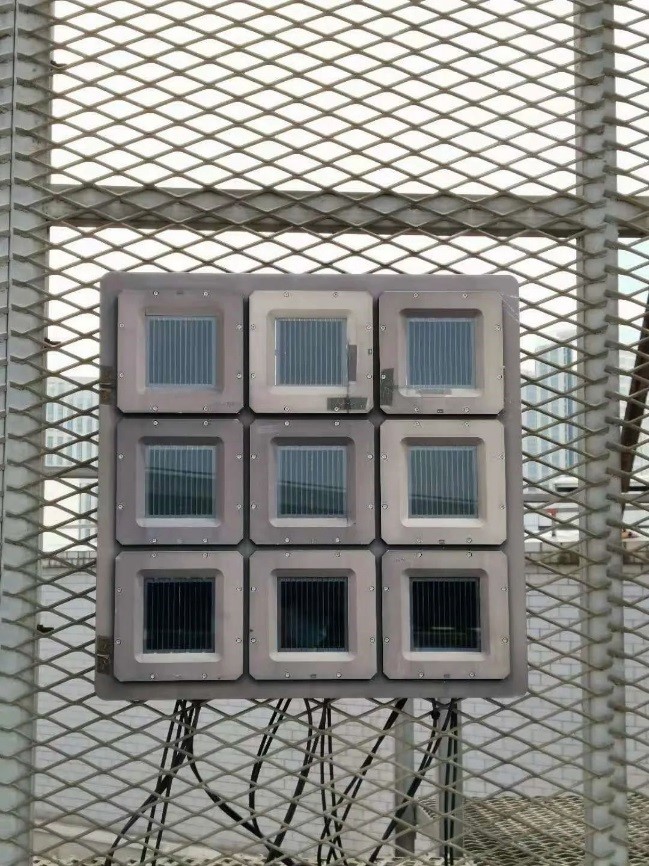

In addition, Prof YANG's team has developed large-area perovskite sub-modules (125 mm × 125 mm) based on the carbon electrodes. They have built the field test system to evaluate the outdoor performance of the perovskite sub-modules and also established a small-scale distributed electricity generation system based on the perovskite modules to evaluate their practical running properties.

The research work was funded by the Shanghai Municipal Natural Science Foundation, the Shanghai Talent Development Foundation, the Strategic Priority Research Program of Chinese Academy of Sciences and the joint research project with an enterprise.

Carbon black interlayer improves the efficiency of all-inorganic perovskite solar cells based on carbon electrodes

Schematic diagram of vacuum-assisted drying process of carbon electrodes and the ToF-SIMS element depth distribution of perovskite/CuSCN films

Field test system for perovskite sub-modules

Reference:

https://pubs.acs.org/doi/abs/10.1021/acsami.0c08006

https://pubs.acs.org/doi/abs/10.1021/acsami.1c05495

Contact:

Prof. YANG Songwang

Shanghai Institute of Ceramics

Email: swyang@mail.sic.ac.cn