Scientists develop the Nano-catalytic Coatings to Solve the Osteogenic Problem of the Implants in Osteoporotic Animals

Oxidative stress will cause irreversible damage to osteoblasts associated with bone loss, which has an adverse effect on fracture repair under pathological conditions. The orthopedic implants with antioxidative capability has thus provided an important therapeutic option to ameliorate osteoblast activity and bone mass around implants in osteoporosis.

Recently, the Plasma Spraying Group in Shanghai Institute of Ceramics, Chinese Academy of Sciences (SICCAS) has made new progress in the research of nano-catalytic coatings for osteoporotic fracture repair. The group constructed titanium oxide nanotube arrays supported cerium oxide nanoparticles on the surface of titanium implants, which can effectively alleviate the damage of oxidative stress to the activity of osteoblasts and solve the osteogenic problem of the implants in osteoporotic animals.

The related result was published in Chem. Eng. J entitled "Titania nanotube array supported nanoceria with redox cycling stability ameliorates oxidative stress-inhibited osteogenesis". The first author is SHAO Dandan, a PhD student in SICCAS, who is supervised by Assoc. Prof. LI Kai and Prof. ZHENG Xuebin.

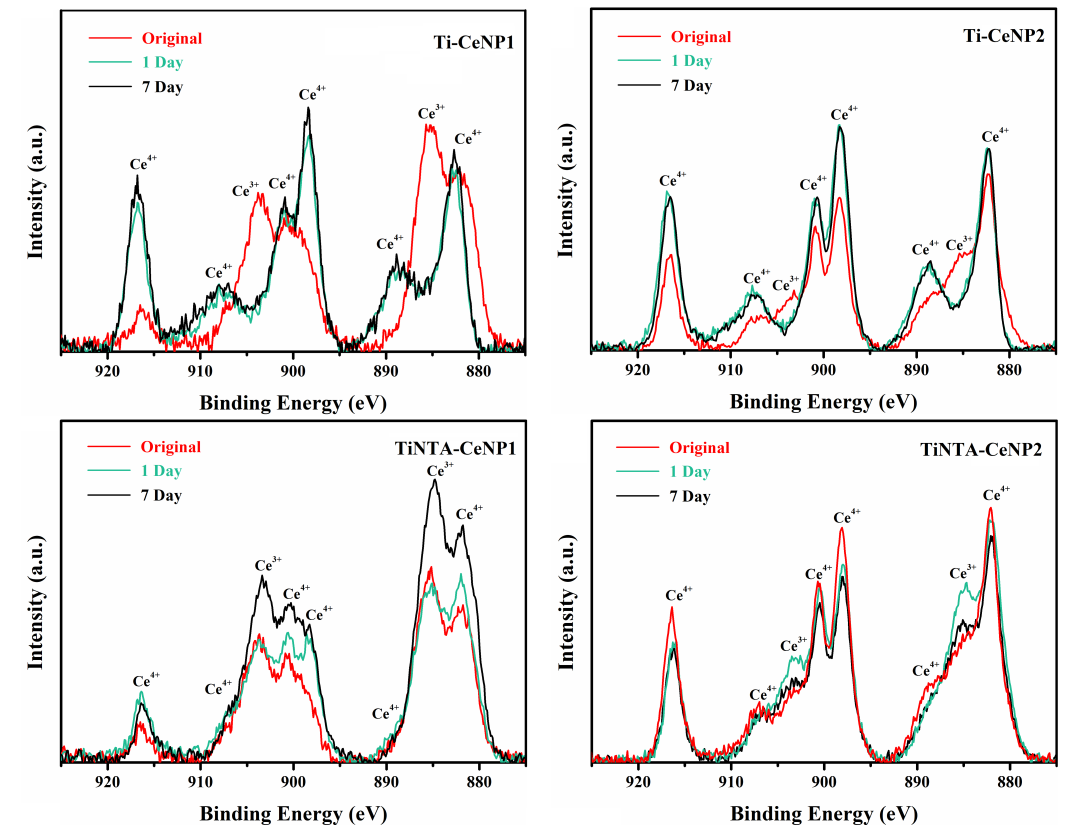

The research founded that vertically aligned titania nanotube array supported CeNPs (TiNTA-CeNPs), regardless of the pre-dominant Ce oxidation state, retained the cycling capability of Ce4+/Ce3+ in H2O2 containing phosphate-buffered saline (PBS) compared with Ti supported CeNPs. Phosphate ions in the physiological environment can easily combine with Ce3+ in CeNPs, hindering the reversible cycle between Ce3+ and Ce4+. However, due to the preferentially ligand exchange between Ti3+ and phosphate on the TiNTA surface, the binding of phosphate ions to Ce3+ is limited, thereby retaining the cyclic antioxidant function of TiNTA-CeNPs.

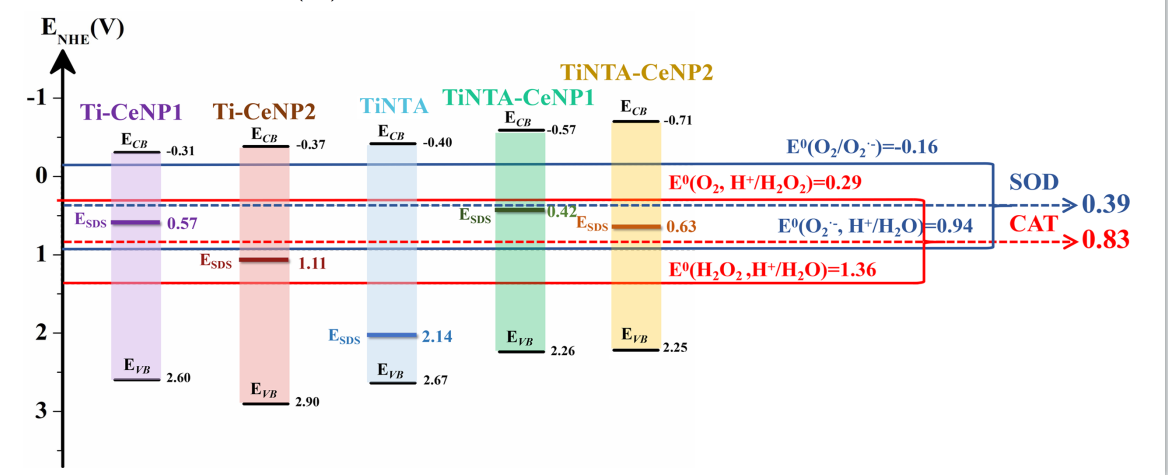

Furthermore, the research group established a correlation between electronic band structures of Ce-Ti mixed oxides and redox potential of reactive oxygen species (ROS) aided in interpretation of enhanced redox cycling capability and enzyme-like activities. The matching degree between the energy of surface defective state (ESDS) and the potential of the redox couple in the catalytic reaction of superoxide dismutase (SOD) and catalase (CAT) can significantly affect the enzyme-like activity of the material. Accordingly, Ce3+-rich TiNTA-CeNP1 and Ce4+-rich TiNTA-CeNP2 in PBS exhibited more sustained superoxide dismutase and catalase mimetic response, respectively.

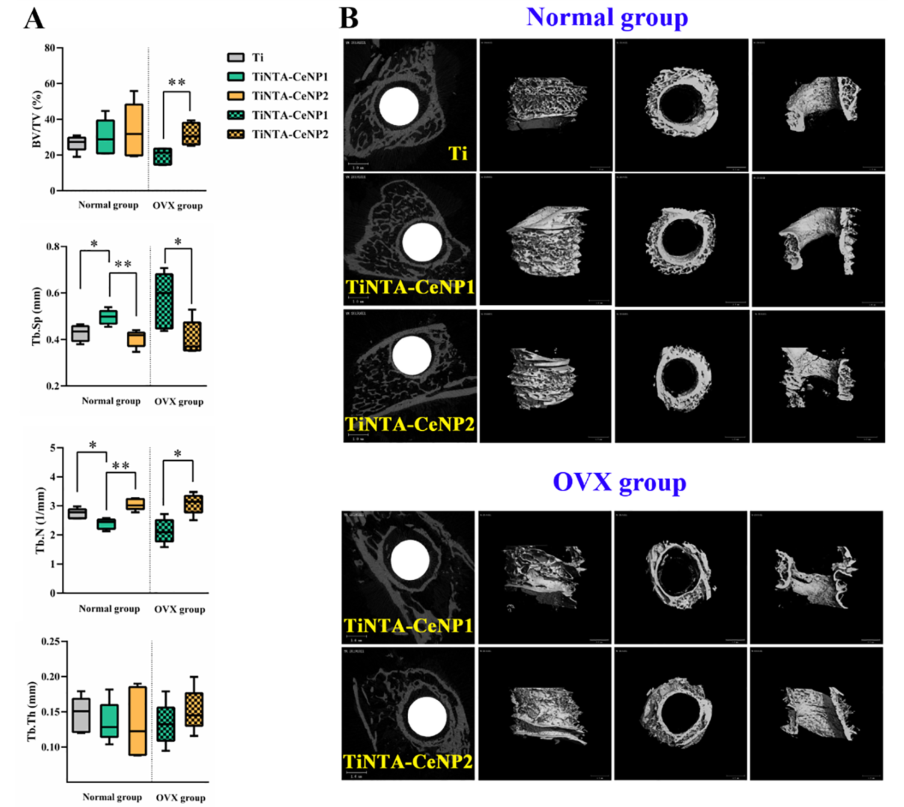

To demonstrate in vivo osteoprotective effect, a rat model of oxidative stress-related osteoporosis was established. It was found that TiNTA-CeNP2 with higher CAT mimic activity and lower Fenton-like activity can significantly reduce the content of reactive oxygen species (ROS) in osteoblasts under oxidative stress, and protect the activity and differentiation ability of osteoblasts from oxidative damage. In addition, TiNTA-CeNP2 can effectively reduce the production of oxidized substances in the tissue surrounding implants in osteoporotic rats, reduce the production of inflammatory fibrous tissue, and better promote bone regeneration.

The research work was supported by the National Natural Science Foundation of China and the Youth Promotion Association of the Chinese Academy of Sciences.

Figure 1. The Ce 3d high-resolution XPS spectra of Ti-CeNPs and TiNTA-CeNPs after immersing in a phosphate buffer solution containing H2O2 for different time.

Figure 2. The relationship between the energy of surface defective state (ESDS) of Ti-CeNPs and TiNTA-CeNPs and the redox pair potential in the catalytic reaction of SOD and CAT.

Figure 3. (A) Quantitative results of BV/TV, Tb.Sp, Tb.N, and Tb.Th of trabecular bone around different implants. Implant loosening of the Ti implant was observed in OVX rats at 8 weeks after implant insertion. (B) The cross-sectional 2D images and the 3D-reconstruction images of peri-implant trabecular bone structure. Scale bar = 1.0 mm. Asterisks indicate significant difference (*P < 0.05, **P < 0.01).

Reference:

https://doi.org/10.1016/j.cej.2021.128913

Contact:

Prof. ZHENG Xuebin

Shanghai Institute of Ceramics

Email: xbzheng@mail.sic.ac.cn