Scientists Develop Novel High-Performance Inorganic Plastic-Deformable Thermoelectric Compounds

Inorganic plastic-deformable thermoelectric compounds can break the limitations of traditional inorganic brittle thermoelectric materials and organic flexible counterparts, offering promise for use in the fields of flexible electronics and power generation.

The scientists from Shanghai Institute of Ceramics (SICCAS) have found the abnormal plastic-deformability at room temperature in inorganic semiconductors Ag2S (Nature Materials, 2018) and Van der Waals single crystal InSe (Science, 2020). They also developed n-type high-performance inorganic flexible/plastic-deformable thermoelectric materials and devices (Energy & Environmental Science, 2019), opening up a new research direction of inorganic plastic-deformable thermoelectrics.

However, the members of inorganic plastic-deformable materials are still scarce. Especially, the p-type inorganic plastic-deformable materials are still absent.

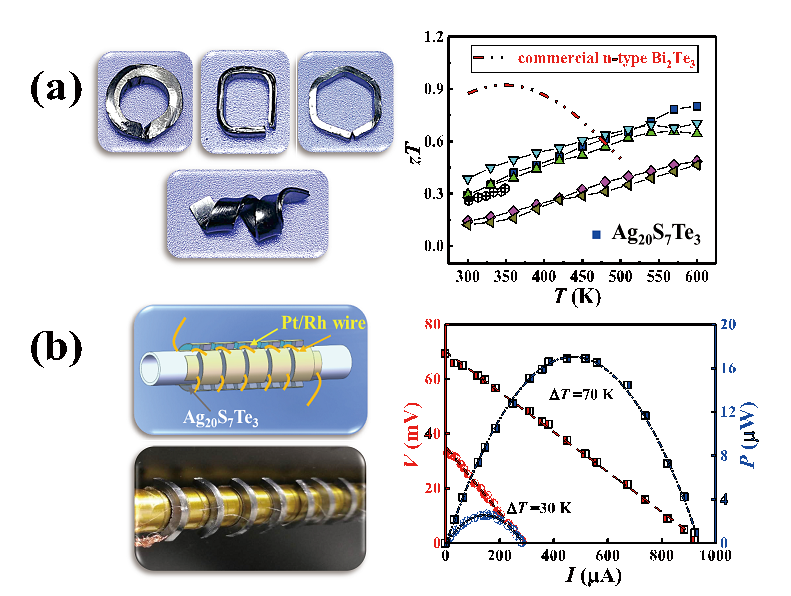

Recently, the scientists from SICCAS and Shanghai Jiao Tong University have developed n-type Ag20S7Te3 and p-type (Ag0.2Cu0.8)2S0.7Se0.3 high-performance inorganic plastic-deformable thermoelectric compounds. By utilizing their extraordinary shape-conformability at room temperature, the researchers fabricated a ring-shaped thermoelectric device which was conformable with curved heat source surface.

Ag20S7Te3 crystalizes in a body-centered cubic structure, which is analogous with that of middle-temperature phase of Ag2S. At ambient temperature, Ag20S7Te3 exhibits even better shape-conformability than Ag2S and could be easily bent into different shapes. The first-principle calculations reveal that cubic-Ag20S7Te3 has a lower generalized stacking fault energy (GSFE) and a higher cleavage energy (CE) than monoclinic-Ag2S, which is responsible for the better shape-conformability of Ag20S7Te3 than Ag2S at room temperature.

At 600 K, the zT of Ag20S7Te3 is 0.8, which is comparable to that of Bi2Te3-based alloys prepared by zone melting method. The researchers connected the bent n-type Ag20S7Te3 stripes and p-type Pt-Rh wires to fabricate a ring-shaped thermoelectric device. Under a temperature difference of 70 K, the maximum output power was 17.1 μW. The related results were published on Advanced Materials (2021, DOI: 10.1002/adma.202007681), with the title of “Ductile Ag20S7Te3 with Excellent Shape-Conformability and High Thermoelectric Performance”.

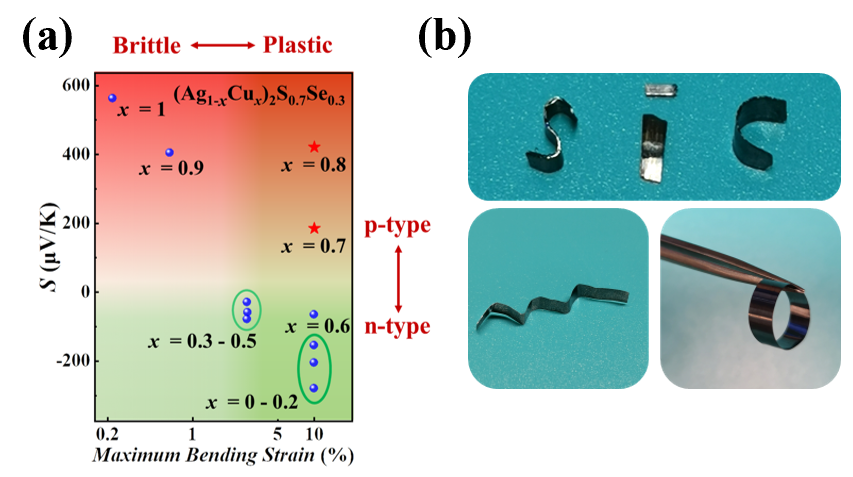

The researchers further selected the n-type Ag2S0.7Se0.3 as the starting material to prepare p-type inorganic plastic-deformable thermoelectric compounds. By alloying Cu atoms in Ag site, they successfully converted its n-type conduction behavior into p-type. When the composition of Cu is in the range of 0.7-0.8, the material shows both plastic shape-conformability and p-type conduction behavior. The first-principle calculations show that (Ag0.2Cu0.8)2S0.7Se0.3 has a high ratio of cleavage energy to slip energy, which is comparable to that of Ag2S0.7Se0.3.

This explains the observed large deformation ability at room temperature. By further introducing Cu vacancy to improve the electrical conductivity, the zT of p-type (Ag0.2Cu0.8)2S0.7Se0.3 can be enhanced to 0.95 at 800 K. The related results were published on Advanced Energy Materials (2021, DOI:10.1002/aenm.202100883), with the title of “p-Type Plastic Inorganic Thermoelectric Materials”.

The related works are supported by the National Key Research and Development Program of China, the National Natural Science Foundation of China, Chinese Academy of Sciences, and Shanghai Rising-Star Program.

References:

https://doi.org/10.1002/adma.202007681

https://doi.org/10.1002/aenm.202100883

Fig. 1 a) Optical images of n-type inorganic plastic-deformable thermoelectric compound Ag20S7Te3 and its thermoelectric performance. b) Ag20S7Te3-based ring-shaped thermoelectric device and its output performance.

Fig. 2 a) Seebeck coefficients and mechanical properties for (Ag1-xCux)2S0.7Se0.3 compounds. b) Optical images of p-type inorganic plastic-deformable thermoelectric compound (Ag0.2Cu0.8)2S0.7Se0.3 with different shapes.

Contact:

Prof. SHI Xun

Shanghai Institute of Ceramics

Email: xunshi@mail.sic.ac.cn