A Device-to-Material Strategy Guides the “Double-high” Thermoelectric Module

Thermoelectric (TE) devices with both high conversion efficiency and high power density (“double-high”) are urgently needed for the applications of power generation. The conventional research approaches on TE devices primarily focus on the realization of high conversion efficiency, but the power density is often overlooked.

Recently, a research team led by Profs. CHEN Lidong & BAI Shengqiang from Shanghai Institute of Ceramics, Chinese Academy of Science has developed a device-to-material strategy to design the “double-high” thermoelectric modules instead of simply pursuing the highest zT value. The new strategy integrates multiple criteria including matching thermal conductivities in p- and n-type thermoelectric materials, optimizing topologic structures of modules, and minimizing interfacial resistance. The study was published in Joule, https://doi.org/10.1016/j.joule.2020.08.009.

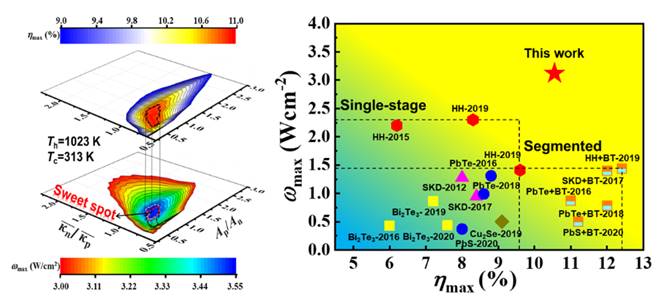

According to the thermal conductivity matching criterion, the n-type Zr0.5Hf0.5NiSn0.97Sb0.03 half-Heusler alloy, which possesses excellent power factor but slightly lower zT, is adopted as the partner of the state-of-the-art p-type Nb0.86Hf0.14FeSb alloy for realizing “double-high” TE module. The newly developed 8-pair module with optimized structure parameters by the full-parameters simulation model achieves the maximum conversion efficiency of 10.5% and maximum power density of 3.1 Wcm-2 at the temperature difference of 680 K, synchronously breaking through the two records in the single-stage TE modules.

The double-high strategy is expected to meet diverse requirements and to promote widespread applications of thermoelectric power generation.

Figure (A) The calculated maximum conversion efficiency (hmax) and power density (wmax) based on the TE material properties as functions of thermal conductivity and cross-section ratio between n- and p-type legs. (B) The maximum conversion efficiency and maximum power density of the “double-high” module compared with the reported advanced modules.

Reference: https://doi.org/10.1016/j.joule.2020.08.009

Contact:

CHEN Lidong

Shanghai Institute of Ceramics

cld@mail.sic.ac.cn