Researchers Make Progress in Single Crystal Fibers for Laser Applications

Single crystal fibers (SCF) are fiber-shaped crystalline materials of diameters varying between tens of microns to 2 mm, which are often referred as a combination of conventional bulk laser crystals and glassy laser fibers. SCFs exhibit a fiber-shaped appearance and maintain the outstanding physical, chemical and optical properties of crystalline materials simultaneously, which makes it possible to combine the advantages of high thermal conductivity, excellent thermal dissipation efficiency, weak negative nonlinear effects, etc. Thus the laser device based on SCF features high peak power of a solid-state laser system and high average power of a fiber laser system simultaneously.

Recently, the Laser and Optical Single Crystals Research Group from Shanghai Institute of Ceramics, led by Prof. SU Liangbi and Prof. WU Anhua, achieved new progresses in SCF. A new Laser-Heated Pedestal Growth (LHPG) apparatus for SCF growth was designed, and Yb:YAG SCFs with diameters of 0.2 mm and lengths of 710 mm was successfully synthesized by this LHPG apparatus. The SCFs exhibit length-to-diameter ratio larger than 3000, which is the record value reported in China, and the fluctuation of diameters is within ±5%. The Yb:YAG SCFs exhibit excellent flexibility and are resistant to bending, indicating potential applications in all-solid-state compact high-power laser systems.

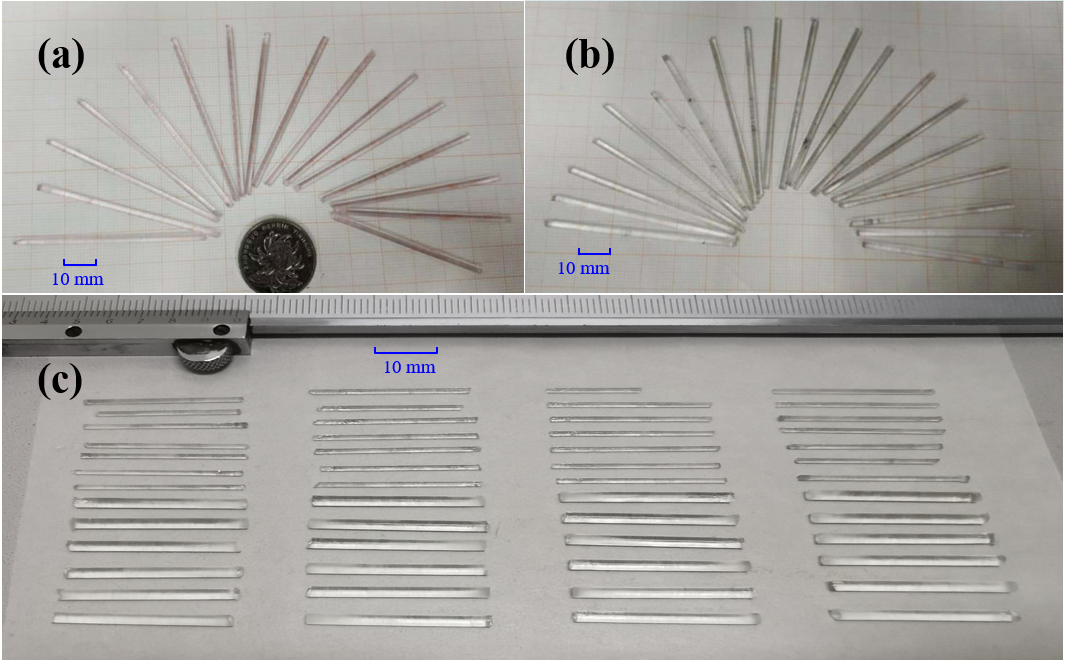

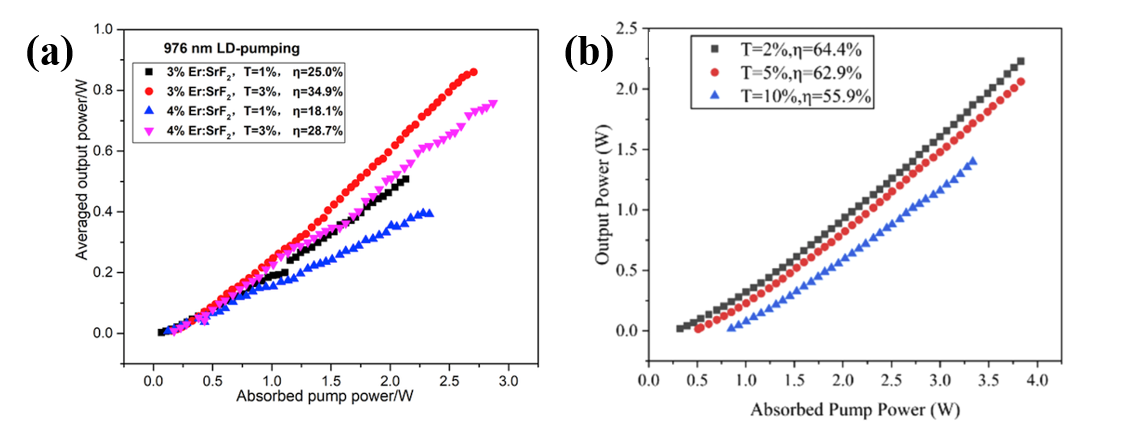

As one of the three fundamental components of “Materials Genome Initiative”, the strategy of high-throughput synthesis can efficiently accelerate the development and application of new materials. Recently, the high-throughput synthesis of fluoride SCFs such as rare earth ions doped CaF2 and SrF2 was achieved in this research group. As much as one hundred fluoride SCFs can be synthesized in one growth by modifying conventional Bridgman technique and designing a particular “multi-microchannel crucible”. The diameters of these SCFs vary between 0.9 mm to 1.9 mm, with lengths up to 60 mm. This “multi-microchannel crucible” crystal growth technique improves the stability, repeatability and efficiency of material experiments by high-throughput synthesis of SCFs with various chemical compositions and dimensions in one growth process using exactly the same experimental condition. At the same time, it provides a technical support for the batch production of these fluoride SCFs, which are potentially to be applied in mid-infrared laser systems. Through the collaboration with research group led by Prof. LIU Jie at Shandong Normal University, CW laser were achieved at mid-infrared regions of 2.8 μm and 1.9 μm with corresponding slope efficiencies of 34.9% and 64.4% respectively, using 3.0 at% ~ 4.0 at% concentrated Er3+:SrF2 and Tm3+:CaF2 SCFs.

The above research progresses have been published in Journal of Synthetic Crystals as a brief report (Journal of Synthetic, 2020, 49: 175), Optical Materials(Optical Materials, 2019, 95: 109255), and Optical Express. (Optics Express, 2020, 28: 6684-6695).

The research activities are supported by National Natural Science Foundation of China (61635012) and Strategic Priority Program of the Chinese Academy of Sciences (XDB16030000), Instrument Developing Project of the Chinese Academy of Sciences (YJKYYQ20170019)、International Partnership Program of Chinese Academy of Sciences (121631KYSB20180045).

Laser Heated Pedestal Growth (LHPG) apparatus for SCF growth

Photo of Φ 0.2 mm × 710 mm Yb:YAG SCFs

High-throughput synthesis of Ф 1.9 mm Er3+:SrF2 SCFs (a)、Ф 1.9 mm Tm3+:CaF2 SCFs (b)、and Ф 0.9 mm、Ф 1.9 mm Tm3+:SrF2 SCFs (c) using “multi-microchannel crucible” crystal growth technique

2.8 μm CW laser output of Er3+:SrF2 SCFs (a) and 1.9 μm CW laser output of Tm3+:CaF2 SCFs (b)

Reference:

Optics Express, 2016, 24: 15522-15527

Applied Physics Reviews, 2017, 4, 011105

Journal of Synthetic, 2020, 49: 175

Optical Materials, 2019, 95: 109255

Optics Express, 2020, 28: 6684-6695

Contact:

Prof. SU Liangbi

Shanghai Institute of Ceramics

suliangbi@mail.sic.ac.cn