Progress in 3D-printing Biomedical Materials at Shanghai Institute of Ceramics

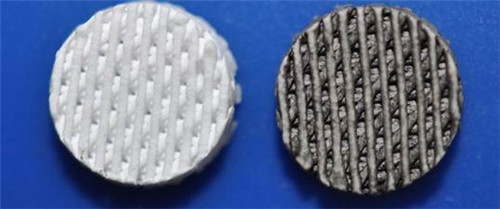

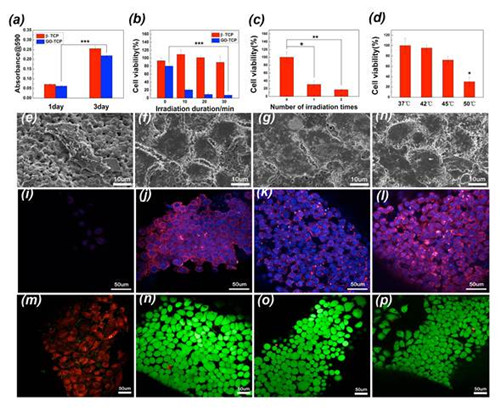

Current treatment of bone tumors in clinic mainly comprises surgical removal of detectable disease and chemo/radiotherapy. However, surgery intervention is generally difficult to eliminate bone-tumor cells completely and leads to large bone defects. The chemo/radiation-resistance and severe side-effect result in endless suffering to patients. Until now, it still remains a major challenge to repair the large bone defects caused from malignant bone tumor removal. The research team at Shanghai Institute of Ceramics, Chinese Academy of Sciences, led by Prof. Wu Chengtie and Prof. Chang Jiang, first proposed a promising idea that combined tissue engineering with photothermal therapy, and recently have made significant progress in the preparation of bifunctional scaffolds for therapy and regeneration of large tumor-related bone defects. In this study, bioceramic/graphene oxide composite scaffolds were fabricated via 3D-printing method (Figure 1). The scaffolds exhibited excellent photothermal effects induced by 808nm NIR irradiation and the final temperature can be regulated. After irradiation at an ultra-low density power (0.36W/cm2), the viability of tumor cells in bifunctional scaffolds decreased by 92.6% (Figure 2). Also, the prepared bifunctional scaffolds exhibited significantly improved bone-forming activity by stimulating osteogenic differentiation of rabbit bone marrow stromal cells and in vivo bone formation. The results suggest that the prepared scaffolds could be used for therapy and regeneration of large tumor-related bone defects. This work may pave the way for tissue engineering by developing novel bifunctional scaffolds with therapy and regeneration capabilities to solve tumor-related tissue defects. The research results have been accepted by Advanced Functional Materials(adfm201504142)(IF 11.8, the first author of the paper is Ma Hongshi, a first year PhD student). The reviewer gave very positive comments: “……The study is well designed with distinct novelty by addressing the key issues that traditional scaffolds do not have such bifunctions for tumor therapy and bone regeneration.”. Recently, one patent about the study has been applied.

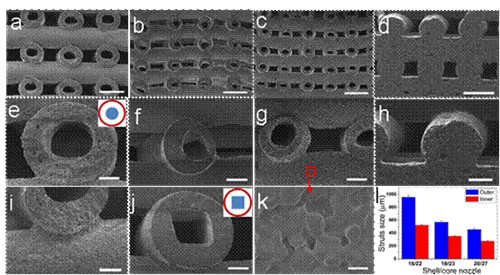

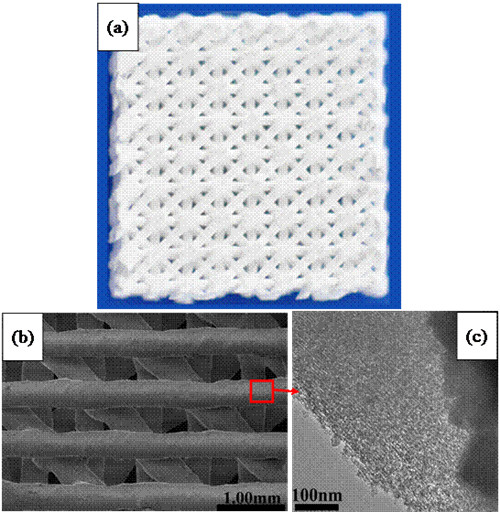

After three years of exploration, the team has successfully solved this problem that the large pore size and morphology cannot be well controlled. Meanwhile, the team have prepared bioceramic scaffolds with multi-scale and complex structure, such as bioceramic scaffolds stacked with hollow channel (Figure 4) and hierarchically porous scaffolds composed of macropores and mesopores (Figure 5). These novel scaffolds well simulated the complex structure of human tissues, and further improved cell attachment and proliferation as well as formation of new bone. These results have recently published. (Nanoscale. 2015; 7(45): 19207-21, ACS Applied Materials & Interfaces. 2015; 7:6541-6549. Acta Biomaterialia. 2014; 10(1): 463-476).

The research was supported by the National High Technology Research and Development Program of China (863 Program), Key Research Program of Chinese Academy of Sciences.

Figure 1. Photograph of 3D printed pure bioceramic scaffold (left) and graphene oxide modified scaffolds (right).

Figure 2. 3D-printing graphene oxide modified bioceramic scaffolds can kill the tumor cells effectively because of excellent photothermal with irradiation (b, c, d, e, f and m), tumor cells still grew well in pure bioceramic scaffolds with (g, k and o) or without irradiation (h, l and p) and graphene oxide modified bioceramic scaffolds without irradiation (a, f, j and n).

Figure 3. IR thermal images (a) and heating curve (b) of tumor-bearing mice exposed to 808 nm laser. The whole-body fluorescence imaging (c) of tumor in four groups at day 0 and day 7, and photograph (e) of tumor in four groups at day 0 and day 14. Relative tumor volume change with increasing days in four groups (d)

Figure 4. Bioceramic scaffolds with hollow channel structures were prepared by 3D printing for regeneration of large bone defects. The shape and scale of hollow channel can be controlled concisely.

Figure 5. 3D-printing hierarchically porous scaffolds were composed of macropores (a, b) and ordered mesopores (c), and promoted formation of new bone.