High-Performance 3D-Printed SiC Ceramics via Pressureless Sintering

Prof. Chen Jian at the Shanghai Institute of Ceramics, Chinese Academy of Sciences has proposed an innovative hybrid process which integrates material extrusion (MEX) printing with precursor infiltration and pyrolysis (PIP) and pressureless solid-state sintering.

Three national invention patents have been filed. The first author of the paper is Gao Chenxi, a direct-entry Ph.D. candidate at the Shanghai Institute of Ceramics, and the corresponding authors are Professor Chen Jian and Professor Huang Zhengren. This research received support from the National Key Research and Development Program of China. The study was published in Additive Manufacturing (https://doi.org/10.1016/j.addma.2025.105024).

The demand for silicon carbide (SiC) ceramic structural components is rapidly increasing in high-end equipment sectors such as semiconductor manufacturing and new energy. In semiconductor manufacturing, SiC ceramics are primarily used for moving parts including wafer stages, guide rails, ceramic chucks, and robotic arms in lithography machines. The high rigidity and low thermal expansion coefficient ensure stable equipment operation with nanoscale motion precision. In the new energy photovoltaic sector, SiC ceramics replace traditional quartz materials in carrier components such as boat holders for diffusion furnaces and LPCVD equipment, extending service life by more than five times. However, the extreme hardness and high brittleness of SiC ceramics make it difficult to fabricate complex structural parts using traditional processing methods, a technical bottleneck that severely restricts their application in high-end equipment.3D printing technology has emerged as a key approach to overcoming the manufacturing limitations of SiC ceramics. Currently, most 3D-printed SiC ceramics are based on reaction-bonded silicon carbide (RBSC), which exhibits high defect tolerance. Nevertheless, RBSC ceramics containa high content of residual free silicon (typically >30 vol%). Since silicon has a melting point below 1410°C, it severely limits the high-temperature performance of these materials, thereby constraining the application of 3D-printed SiC ceramics in extreme service environments.

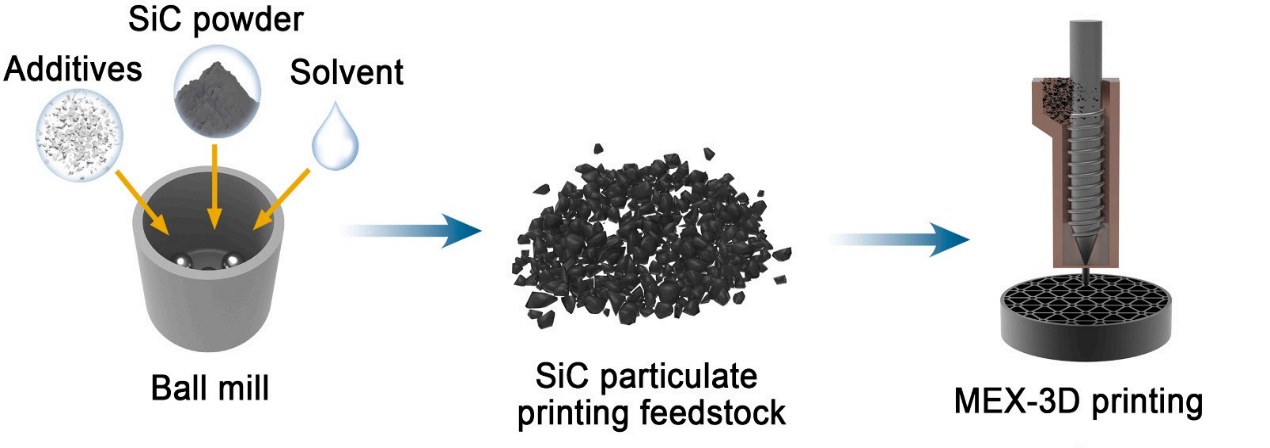

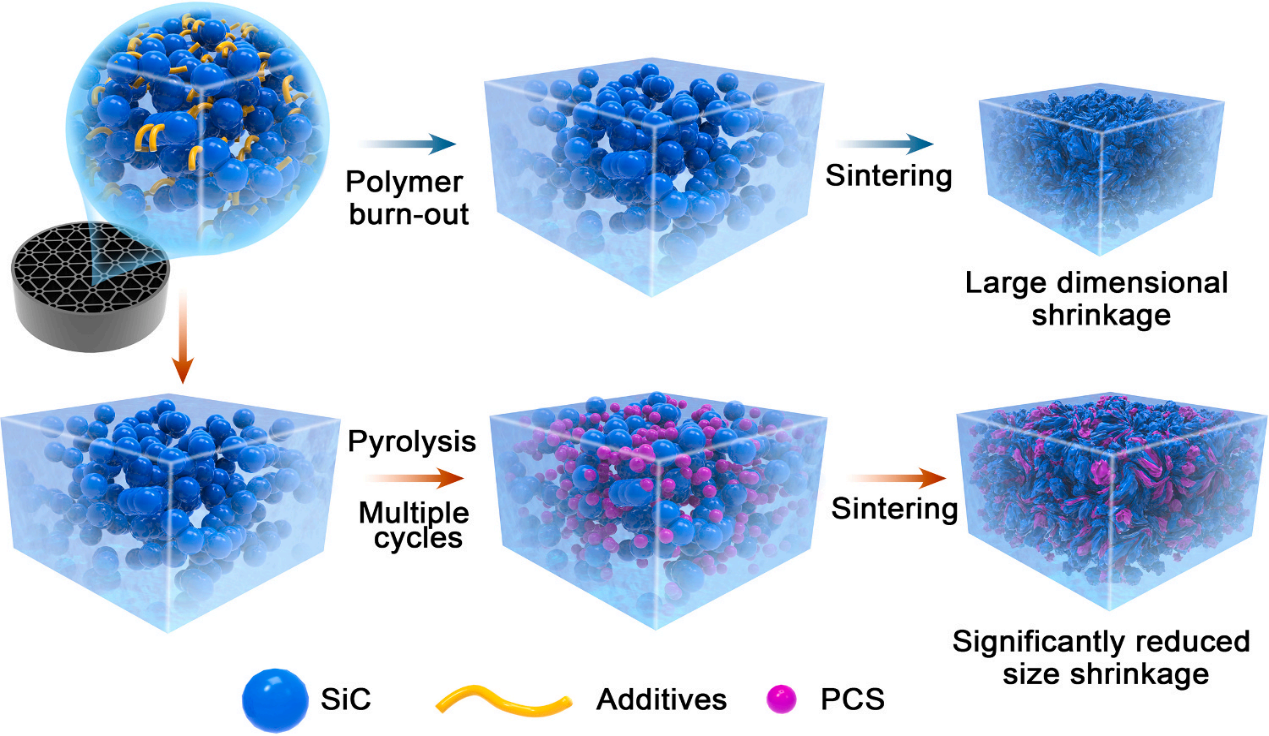

The team has proposed an innovative hybrid process. This method integrates material extrusion (MEX) printing with precursor infiltration and pyrolysis (PIP) and pressureless solid-state sintering. The pressureless solid-state sintering route effectively avoids excessive silicon phase content, thereby improving the material’s high-temperature performance in extreme environments. However, 3D-printed SiC ceramics manufactured via pressureless sintering contain 40–50 vol% organic binders. The pores formed during sintering can lead to shrinkage exceeding 20%, resulting in significant loss of dimensional accuracy and even material cracking. To overcome these issues, the team introduced vacuum impregnation and pyrolysis of polycarbosilane (PCS) precursor into the 3D-printed porous green body. This process converts PCS into in-situ nano-SiC particles at 1300°C, filling the pores and constructing an internal micro-support skeleton. Additionally, to enhance the low strength of the green body, a pre-sintering treatment (1750–2050°C) was applied. This step increases the green body’s strength while maintaining an appropriate open-pore structure, enabling efficient PCS infiltration and defect control. This innovative process achieves a dual breakthrough: on one hand, it completely avoids the formation of free silicon during sintering, giving the material excellent high-temperature mechanical properties; on the other hand, the SiC skeleton formed during the PIP process effectively inhibits sintering shrinkage, reducing the linear shrinkage rate significantly from 21.71% to 6.38%.The final prepared SiC ceramic achieves a density of 3.17 g·cm⁻³, a flexural strength of 359 MPa, an elastic modulus of 381 GPa, and a thermal conductivity as high as 165.76 W·m⁻¹·K⁻¹. Even at 1500°C, it maintains a flexural strength of 357 MPa, providing reliable technical support for the precision manufacturing of complex SiC ceramic components used in extreme environments.

Schematic diagram of the MEX-3D printing process for SiC ceramics

Dimension control of SiC Ceramics fabricated via MEX and pressureless solid-state sintering using the PIP strategy

Mechanical and thermal properties of SiC ceramics fabricated by MEX and pressureless solid-state sintering

CHEN jian

Shanghai Institute of Ceramics

E-mail: nannancj@mail.sic.ac.cn