Achieves Significant Progress in Development of 3D Printing Silicate-based Bioceramic Dental Product

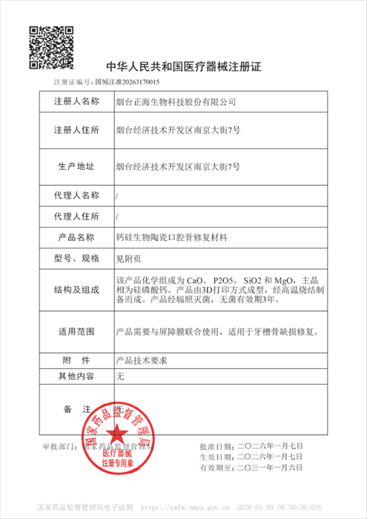

Recently, the 3D-printed calcium-silicate bioceramic oral bone repair material, which is launched based on the technology transfer of the "3D-printed bredigite bioactive ceramics bone implant" project led by Prof. Chengtie Wu's research team at the Shanghai Institute of Ceramics, is developed by Yantai Zhenghai Bio-Tech Co., Ltd. (abbreviated as "ZH-Bio") has successfully obtained Class III Medical Device Registration Certificate (National Medical Device Registration Certificate No.20263170015). As the first 3D-printed calcium-silicate-based bioceramic material with biomimetic porous structure for oral bone repair in China, this product marks a significant advancement in translation in the field of silicate-based bioceramics in Shanghai Institute of Ceramics from the basic research into clinical applications.

The 3D-printed calcium-silicate bioceramic bone repair materials are primarily used for the treatment of alveolar bone defects. Alveolar bone defects represent a highly challenging clinical issue, not only severely impairing the basic physiological functions of patients, such as mastication, swallowing, and respiration, but also causing significant psychological distress and facial appearance concerns. Since its establishment in 2001, the Biomaterials and Tissue Engineering Research Group at the Shanghai Institute of Ceramics has focused on the application of inorganic biomaterials for tissue regeneration and repair. The group pioneered the development of a silicate-based biomaterial library including various bioceramics such as bredigite, and systematically elucidated the regulatory effects and mechanism of bioactive ionic release from bioceramics on the regeneration and repair of tissues such as bone and blood vessels. Since 2011, the group has further integrated silicate-based bioceramics with 3D printing technology to achieve precise construction of macroscopic complex shapes and microscopic pore structures in bioceramics. Notably, the group was the first internationally to propose and implement the concept of biomimetic structure construction in bioceramics, demonstrating that biomimetic structural features enhance the vascularized regeneration and repair in large bone defects. These research findings have been published in high-impact international journals such as Advanced Materials, Science Advances, Materials Today and National Science Review. The group has filed over 90 patents and received the "First Prize of Shanghai Natural Science Award”, providing an innovative solution to address the challenges of maxillary bone defect treatment.

To achieve the industrial transformation and clinical application of the aforementioned scientific research outcomes, the Biomaterials and Tissue Engineering Research Group established an official collaboration with ZH-Bio in 2014. In 2016, Prof. Chengtie Wu, the leader of the research team, successfully obtained the "Taishan Industrial Leading Talent" award through a joint application with ZH-Bio, and initiated the "Industrialization of Novel Porous Silicate-Based Bioactive Bone Repair Materials via 3D Printing" project. In 2017, Prof. Chengtie Wu completed the technology transfer for the "3D-Printed Bredigite Bioactive Ceramic Artificial Bone" project, leading the research team to collaborate with ZH-Bio on the industrialization and clinical translation of 3D-printed calcium-silicate-based bioceramic for alveolar bone defect treatment. Throughout subsequent collaborations, the research team worked closely with ZH-Bio by assisting in critical industrialization milestones such as product formulation optimization, process validation, and technical scaling. The 3D-printed calcium-silicate-based bioceramic oral bone repair material successfully passed medical device registration inspections and underwent multicenter randomized controlled clinical trials at multiple clinical hospitals, including Wuhan University School of Stomatology and Nanjing Medical University Affiliated Stomatology Hospitals. The results demonstrated that the product significantly promotes the repair and regeneration of alveolar bone defects while exhibiting excellent biocompatibility. After eight years of close collaboration between the parties, the 3D-printed bioceramic bone repair product for oral application was approved for the first domestic Class III medical device registration certificate.

Calcium silicate bioceramic bone repair material for oral use

Medical device registration certificate

This achievement marks the formal clinical application of the research outcomes of silicate-based bioceramics for bone regeneration and repair by the Shanghai Institute of Ceramics, which will play a positive role in realizing the goal of "accelerating the construction of a healthy China" in the national 15th Five-Year Plan. This achievement demonstrates the key "source" role of innovative research results in generating high-value medical devices, and serves as a typical example of industry-university-research-medical collaboration in achieving the industrial and clinical transformation of scientific research outputs. At present, the biomaterials and tissue engineering research team at the Shanghai Institute of Ceramics is continuing to carry out the transformation of research results on silicate-based bioceramics for the regeneration of other complex tissues such as skin and joints, and has achieved significant progress in stages. It is expected that more medical devices will be developed for clinical application in the next three years.