Scientists Achieve Important Advances on Bi2Te3-based plastic thermoelectric materials

Bi2Te3-family thermoelectric (TE) materials, including Bi2Te3, Bi2Se3, Sb2Te3, and their pseudo-binary solid solutions semiconductors, are widely used for solid-state refrigeration, precise temperature control, and local thermal management. However, it is widely recognized that the Bi2Te3-family TE materials are brittle and prone to break under mechanical loading,which greatly limits their application in flexible and micro-electronics. In prior work, researchers from Shanghai Institute of Ceramics show that the antisite defects can lead to high-density, diverse microstructures in classic bulk semiconductor Bi2Te3, which can substantially affect mechanical properties and thus successfully transform itfrom brittle to plastic (Science 2024). Nevertheless, Bi2Se3, Sb2Te3, and their pseudo-binary solid solutions with Bi2Te3 might possess distinct plasticity with that of Bi2Te3 at room temperature, but the related investigation has not been reported yet.

(https://doi.org/10.1038/s41467-025-60465-2)

Recently, the researchers from Shanghai Institute of Ceramics, in collaboration with the Hangzhou Institute for Advanced Study, further clarified the relationship among the native defects, microstructures, mechanical properties of Bi2Se3, Sb2Te3, and their solid solutions with Bi2Te3. Firstly, the Bi2Te3, Bi2Se3, and Sb2Te3 bulk crystals were grown by the temperature gradient method. The Bi2Se3 and Sb2Te3 crystals have an engineering strain less than 5% along the in-plane direction in the three-point bending test. This value ismuch lower than those of the Bi2Te3 crystals (> 20%), indicating their poor plasticity. Scanning transmission electron microscopy characterizations reveal that the Bi2Se3 and Sb2Te3 bulk crystals have highly regular atomic arrangements, which are different with the existence of high-density, diverse microstructures in bulk Bi2Te3 crystals. Such difference is found to be originated from the different dominant native defects in these three compounds. In Bi2Te3, when the defect formation energies of BiTe and TeBi antisite defects are the same, the corresponding value is about 0.63 eV. In Bi2Se3, when the defect formation energies of BiSe and SeBi antisite defects are the same, the corresponding value is about 1.32 eV. In Sb2Te3, only when the anion chemical potential is tuned to the vicinity of the extreme Te-rich point, SbTe and TeSb can own the same formation energy. However, in experiment, this point is difficult to be achieved. Thus, in either Bi2Se3 or Sb2Te3, the antisite defects are difficult to coexist, leading to the highly regular atomic arrangements as well as poor plasticity.

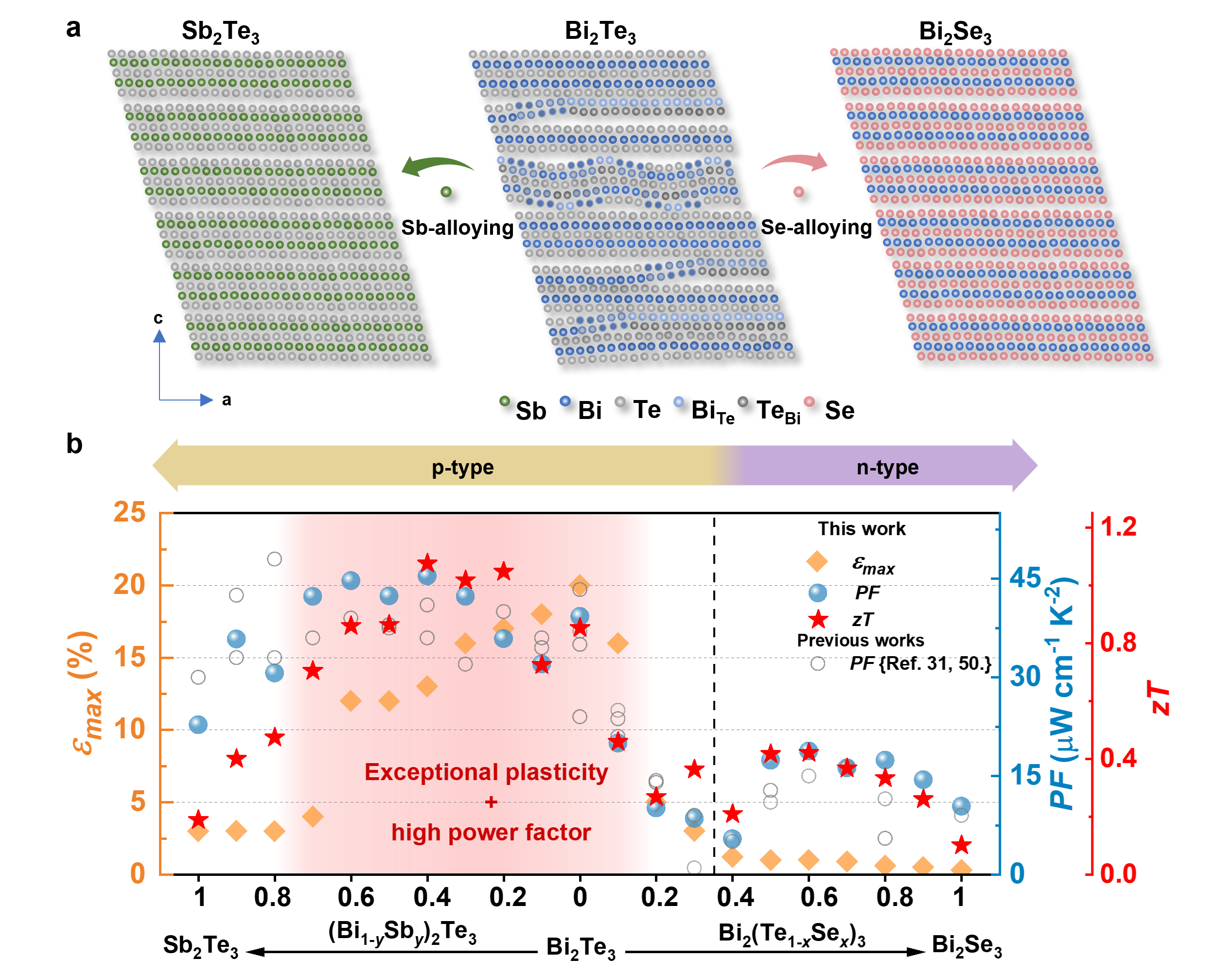

Then, a series of Bi2(Te1-xSex)3 and (Bi1-ySby)2Te3 bulk crystals are grown by the temperature gradient method. Room-temperature mechanical property measurements indicate that the plasticity is significantly decreased with increasing the Se/Sb content in Bi2Te3. When y < 0.7 or x < 0.2, the maximum bending strain is over 10% along the in-plane direction andthe crystals exhibit excellent plasticity comparable to that of Bi2Te3. Microstructure characterizations show that there are still high-density, diverse microstructures in plastic Bi2(Te,Se)3 and (Bi,Sb)2Te3. In addition, with increasing the Sb-alloying content, the hole concentration in Bi2Te3 crystals is gradually increased, while Se alloying converts the majority carrier type from holes to electrons. Furthermore, with increasing the Sb/Se alloying content in Bi2Te3, the lattice thermal conductivity is greatly reduced. Combining the measured maximum strains in the three-point bending test and the measuredroom-temperature power factor (PF) and TE figure-of-merit (zT), the composition range for the Bi2(Te1-xSex)3 and (Bi1-ySby)2Te3 bulk crystals that simultaneously possess exceptional plasticity with the maximum bending strain > 10%, high PF > 20 μW cm−1K−2, and high zT > 0.6 is determined as 0 ≤ y < 0.7.

This work not only expands the research scope of plastic inorganic thermoelectric materials based on Bi2Te3, but also provides a deep understanding on the relationship among native defects, microstructures, and mechanical properties in thermoelectric materials. The related findings were published in Nature Communications (2025).

This work was supported by the National Key Research and Development Program of China, National Natural Science Foundation of China, and the Chinese Academy of Sciences Project for Young Scientists in Basic Research.

Fig. 1 Room-temperature plasticity, conduction behavior, power factor (PF), and figure-of-merit (zT) for Bi2(Te1-xSex)3 and (Bi1-ySby)2Te3 bulk crystals.

Fig. 2 Formation energy of native defects in Bi2Te3, Bi2Se3, Sb2Te3 and the formation energy of different defective structures in Bi2Te3 relative to that containing isolated antisite defects.

Contact: Pengfei Qiu

Shanghai Institute of Ceramics Chinese Academy of Sciences

E-mail: qiupf@mail.sic.ac.cn