Significantly Improved Stability Of VO2 Thermochromic Films By Interfacial Encapsulation (Matter)

The energy crisis is a major issue facing human society today. Buildings account for more than 1/3 of the world's total energy consumption, and nearly half of it is lost through building windows. Vanadium dioxide (VO2) is a typical thermochromic phase change material that has been used in the development of thermochromic smart windows due to its adjustable phase change temperature around room temperature and its remarkable optical response before and after the phase change. Through the unremitting efforts of researchers in recent years, research work on VO2 smart windows has made continuous progress, with breakthroughs in its phase change temperature, optical properties, and large-scale preparation methods. However, the instability and degradation of VO2 materials are still one of the biggest obstacles to their commercialization. Since V is a multivalent element, the +4-valent V ions in VO2 are oxidized to +5-valent V ions by moisture and oxygen in the air, which leads to the failure of thermochromic films. Currently, due to the lack of research on the deterioration process of VO2 films, most literature reports do not yield stability enhancement applicable to commercialization.

Recently, a team led by researcher Ping Jin at the Shanghai Institute of Silicate, Chinese Academy of Sciences, has successfully achieved a significant improvement in the stability of VO2 thermochromic films using an interfacial encapsulation. By constructing sample structures with different interfacial exposures, it was demonstrated that the cross-sectional part of the VO2 film, although its area is small (the area ratio of cross-section to surface in this study is 1:200000), plays a crucial role in its deterioration process, which is often neglected in previous studies. The research team selected HfO2 with matched optical constants and self-hydrophobicity as the protective layer material to simultaneously clad different interfaces (surface and cross-section) of VO2 films, which can achieve a significant increase in the service life of VO2 films while improving their thermochromic effect. The interfacial lad structures can be relatively stable for more than 100 days under high temperature and high humidity accelerated aging tests (60°C, 90% RH), while the structures of samples with arbitrary interfacial exposure are quickly damaged. The Hallberg-Peck model calculation shows that the structure is expected to be stable in service for more than 16 years in a real environment. Meanwhile, the structure exhibits significantly enhanced stability in both boiling water bath experiments and heating experiments, which can meet the use of VO2 films in different environments. This study provides a new strategy for improving the stability of VO2 films and achieving corresponding commercial applications. The related research work was published in Cell Press' flagship materials journal Matter (Matter, 2019; DOI: https://doi.org/10.1016/j.matt.2019.04.004), with first author Tianci Chang, a PhD student at the Shanghai Institute of Silicate, and supervised by researcher Ping Jin and associate researcher Xun Cao.

This research was supported by the National Natural Science Foundation of China, the Young Innovation Promotion Council of the Chinese Academy of Sciences, and the Shanghai Pujiang Talent Program.

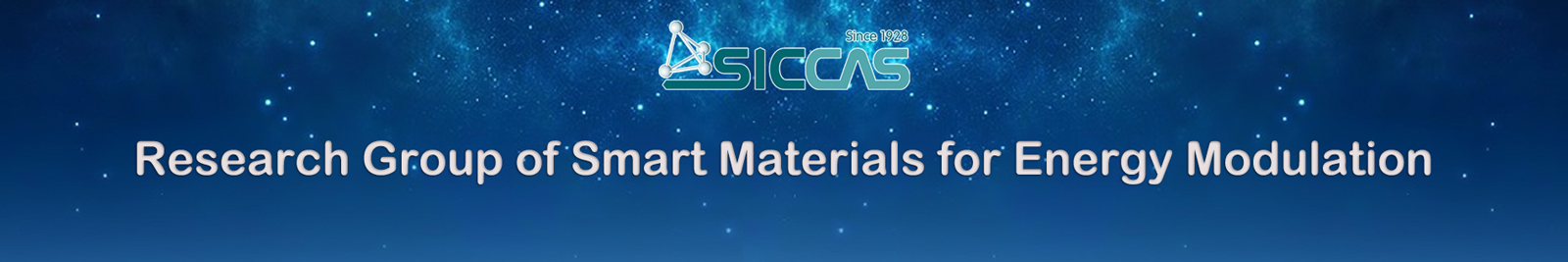

VO2/HfO2 bilayer protection structure and corresponding high/low temperature transmittance spectra, where VO2 reflects hydrophilic surface and HfO2 reflects hydrophobic surface.

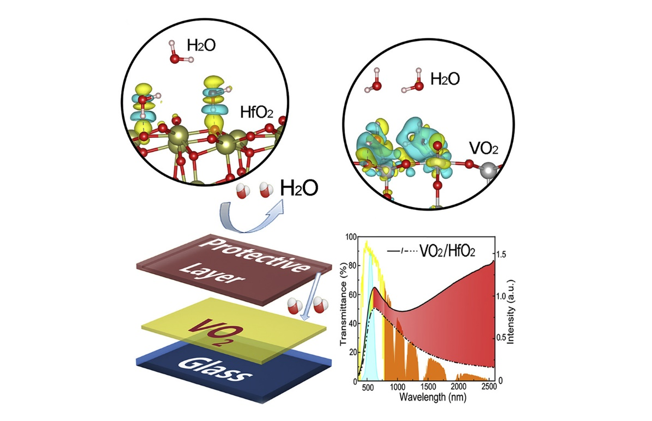

(A) Possible interaction between water molecules and vanadium dioxide surface and hafnium dioxide surface, respectively. V, Hf, O, and H atoms are represented by balls in gray, gold, red, and white, respectively.

(B) Water contact angle measurement of different oxide films. The static water contact angle is about 25.0° for VO2 single-layer film, which means a hydrophilic surface. The introduction of the HfO2 layer makes the static water contact angle of the film change abruptly from 25.0° (hydrophilicity) to 102.0°(hydrophobicity).

(C) Schematic illustrations of four types of samples.

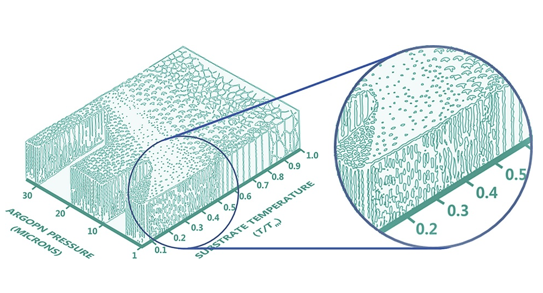

The structure of magnetron sputtered films is related to temperature and air pressure. According to the common parameters of VO2 films prepared by magnetron sputtering, it can be found that the cross-section of the films has certain micro-pores and cracks that can act as a channel for oxygen and moisture and lead to the degradation of the films. The experimental characterization shows that the cross-sectional part of the VO2 film plays a crucial role in its deterioration process.