3D Bioprinting of Multicellular Scaffolds Help Regeneration of Complex Osteochondral Tissues

The integrated regeneration of cartilage and subchondral bone tissue remains a clinical challenge due to the complexity of osteochondral tissues. 3D bioprinting is an advanced biomanufacturing technology, which can easily realize the precise distribution of multiple biomaterials, cells and bioactive factors. It has great potential to reconstruct complex tissues and organs by applying 3D bioprinting technology.

However, it is still a huge challenge for the biomimetic reconstruction of complex osteochondral tissues, due to the tissue linage differences and anisotropic physiological characteristics in cartilage and subchondral bone. Thus, Based on the different cell types and physiological requirements between cartilage and subchondral bone, it is of great importance to develop a 3D multicellular scaffold that can simultaneously simulate the structure and functional characteristics of the osteochondral tissues.

The research team at Shanghai Institute of Ceramics, Chinese Academy of Sciences, led by Prof. WU Chengtie and Prof. CHANG Jiang, has made great progress in 3D bioprinting of multicellular scaffolds for osteochondral regeneration. By designing the bioinks incorporating inorganic biomaterials and the spatial distribution of mutiple cells, the research team constructed a multicellular system containing chondrocytes and mesenchymal stem cells by applying 3D bioprinting technology. The multicellular system simulated the anisotropic physiological characteristics of the osteochondral tissues, and could efficiently promote the regeneration of osteochondral tissues. The result has been published in Materials Today (doi.org/10.1016/j.mattod.2021.04.016). The first author is Chen Qin, a PhD student from Shanghai institute of ceramics, CAS, and her supervisor is Prof. Chengtie Wu.

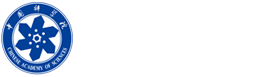

The research team developed a bioink based on Li-Mg-Si (LMS) bioceramics and applied the bioink to prepare a multicellular scaffold by 3D bioprinting. By controlling the composition and distribution of the bioinks and cells, a multicellular system containing chondrocytes and mesenchymal stem cells was constructed to simulate the anisotropic physiological environment of osteochondral tissues. The bioprinted co-culture scaffold was designed with two layers, in which the top cartilage layer was hydrogel bioink loaded with chondrocytes, and the bottom subchondral bone layer was LMS bioceramics-containing bioinks loaded with mesenchymal stem cells. Such a constituent and spatial design of cells and bioinks well met the requirements of cell proliferation and differentiation in cartilage and subchondral bone.

Moreover, the LMS bioceramics-containing bioinks could not only simulate the component of bone, but also release bioactive ions to induce multiple cells towards specific differentiation, thus stimulated the regeneration of both cartilage and subchondral bone simultaneously.

The 3D bioprinted multicellular scaffolds exhibited excellent cell activities, capabilities of simultaneously modulating the specific differentiation of multiple cells in vitro and effectively accelerating the repair of large osteochondral defects in vivo. The main advantages of the bioceramic bioink-based multicellular 3D bioprinting strategy are as follows: i) With just one inorganic biomaterial, the bioink provided a favorable microenvironment for the proliferation and differentiation of multiple cells; ii) Taking the advantages of 3D bioprinting, a multicellular scaffold could be constructed to mimic the complex osteochondral tissues, and different types of cells (chondrocytes and mesenchymal stem cells) could be accurately arranged in the three-dimensional space. The strategy provides new ideas for the reconstruction of complex tissues and organs in the human body.

The study was financially supported by the National Key Research and Development Project, the Natural Science Foundation of China and the Innovation Cross Team of Chinese Academy of Sciences.

Combining LMS bioceramics-containing bioinks and multi-cells, a bilayered multicellular scaffold mimicking osteochondral tissues was successfully prepared by 3D bioprinting method.

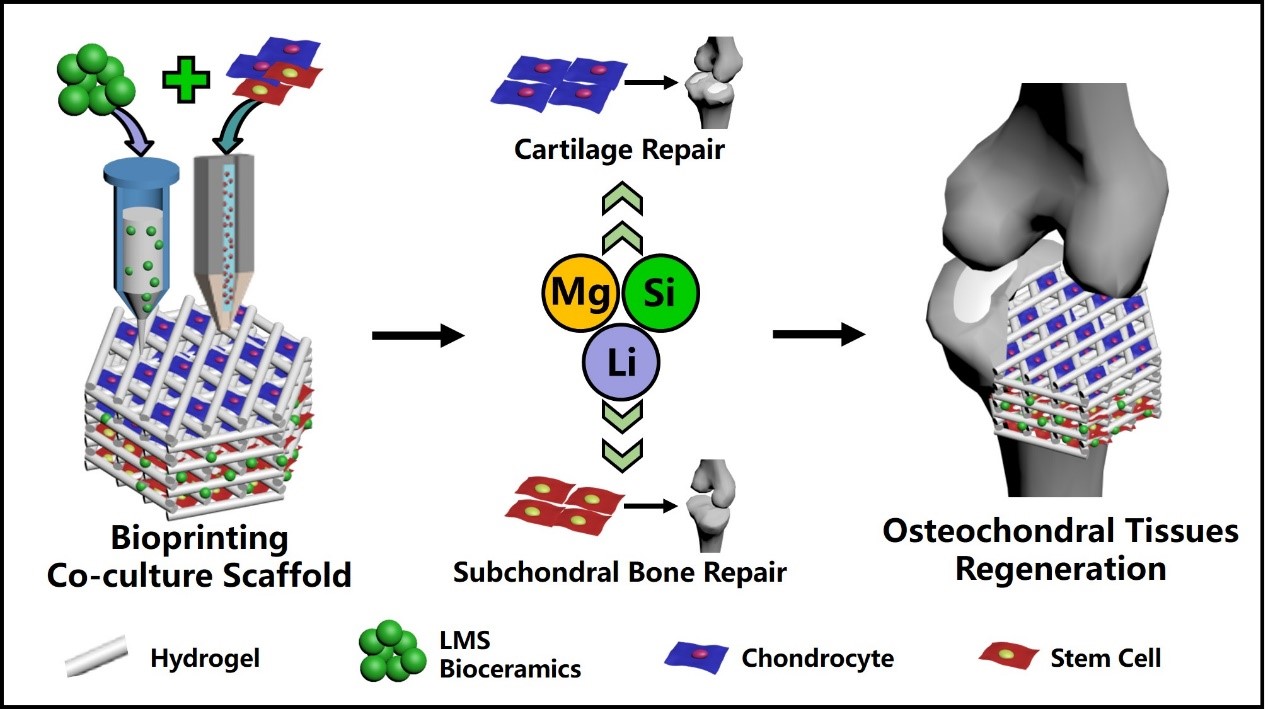

3D bioprinted multicellular scaffolds exhibited excellent cell proliferation and spatial cell distribution mimicking osteochondral interface. (A) The printing process of 3D bioprinted multicellular scaffolds. (B) Proliferation of 3D bioprinted multicellular scaffolds with different bioceramic LMS concentrations. (C) Photographs of the multicellular scaffolds with different LMS concentrations after bioprinting and live/dead assay of the scaffolds (live cells: green fluorescence, dead cells: red fluorescence). (D) Spatial layered distribution of the two cells (RCs in upper layer were labeled with red fluorescence, and hpMSCs in lower layer were labeled with green fluorescence) in the 3D bioprinted scaffolds.

The effect of 3D bioprinted multicellular scaffolds on the repair of rabbit osteochondral defects. Histological analysis showed that the 3D bioprinted scaffolds can promote the regeneration of both cartilage and subchondral bone. (A) Safranin-O/Fast Green histological staining images. (B) Van Gieson staining histological staining images. (C) Histological analyses scores of the sections according to O’Dorscoll grading system.

Reference:

doi.org/10.1016/j.mattod.2021.04.016

Contact:

Prof. WU Chengtie

Shanghai Institute of Ceramics

Email: chengtiewu@mail.sic.ac.cn