Significant Progress in controlled Synthesis and Self-Assembly of Nano-Structure Achieved by SICCAS

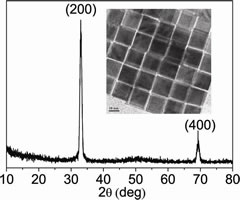

Recently the research group led by Prof. Lian Gao of Shanghai Institute of Ceramics CAS has achieved significant progress in controlled synthesis and self-assembly of nano-structure. By adjusting shape and size of surfactant, Ceria nanocubes of different sizes bounded by six {100} planes were obtained with controlled synthesis, and were self-assembled directionally. The research results were published in a famed publication of Journal of the American Chemical Society on the edition of July 26th. All three reviewers of the journal highly evaluated the significance of the work: the paper reports interesting directional self-assembly of ceria nanocubes; the directional structure is important for understanding crystallographic characteristics of nano-materials and exploring application of nanocrystallites in catalyze, magnetics and electronics.

Recently the research group led by Prof. Lian Gao of Shanghai Institute of Ceramics CAS has achieved significant progress in controlled synthesis and self-assembly of nano-structure. By adjusting shape and size of surfactant, Ceria nanocubes of different sizes bounded by six {100} planes were obtained with controlled synthesis, and were self-assembled directionally. The research results were published in a famed publication of Journal of the American Chemical Society on the edition of July 26th. All three reviewers of the journal highly evaluated the significance of the work: the paper reports interesting directional self-assembly of ceria nanocubes; the directional structure is important for understanding crystallographic characteristics of nano-materials and exploring application of nanocrystallites in catalyze, magnetics and electronics.

As one of the most reactive rare earth materials, ceria (cerium oxide, CeO2) has attracted a great deal of attention due to its unique applications in conversion catalysts, three-way catalysts (TWCs), fuel cells, solar cells, gates for metal-oxide semiconductor devices and phosphors. Experimental and theoretical studies have shown surface structure dependent reactivity of ceria nanocrystallites, and the (100) terminated surface is more reactive and catalytically important than (111) and (110) surfaces. Ceria nanocubes obtained by the research group were bounded by six {100} planes, and were easy to self-resemble through dipole moment perpendicular to surface to form ordered structures, which provides a brand new method to obtain ceria {100} plane surface. Furthermore, due to the presence of oriented aggregation growth, the synthesized ceria nanocubes exhibit fantastic structural properties. Ceria nanocubes of uniformly large size, 1 dimension nanorod of high anisotropy, or even mesocrystal structure could be obtained in oriented aggregation growth by adjusting experimental conditions. The forming mechanism of the nanocrystallites introduced a new method and theoretic foundation for nanocrystallites doping and heterogeneous nano-structure.